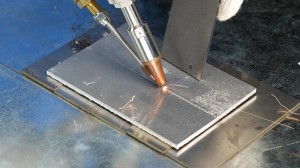

Hauv kev tsim khoom niaj hnub, daim ntawv thov ntawm2000W Fiber Laser Vuam MachineRau vuam aluminium meters tau dhau los ua ntau ntau. Txawm li cas los xij, kom ntseeg tau tias vuam zoo thiab kev nyab xeeb, cov ntsiab lus tseem ceeb hauv qab no yuav tsum tau sau tseg.

1. Nto Kev Kho Mob Ua Ntej Vuam

Cov yeeb yaj kiab oxide nyob rau saum npoo ntawm txhuas hlau tuaj yeem cuam tshuam rau lub vuam zoo. Kev kho kom txhij rau kev kho kom huv yuav tsum tau nqa tawm kom tshem tawm cov yeeb yaj kiab oxide, roj stains thiab lwm yam impurities. Thaum muaj qee qhov chaw lag luam Automotive cov ncej zoo, vim yog kev tsis saib xyuas saum npoo av, ntau ntawm cov hws thiab cov kab nrib pleb uas tau tshwm sim hauv Weld, thiab tus nqi tsim nyog tau poob loj heev. Tom qab kev txhim kho cov txheej txheem kho mob, tus nqi tsim nyog tau sawv ntau dua 95%.

2. Xaiv cov vuam vuam qhov ntsuas hluav taws xob tsim nyog

Vuam qhov tsis xws li lub zog laser, vuam ceev thiab tsom txoj haujlwm yog qhov tseem ceeb. Rau cov phaj txhuas nrog ib tuab ntawm 2 - 3mm, lub zog ntawm 1500 - 1800W tsim ntau dua; Rau cov neeg uas muaj 3 - 5 hli, 1800 - 2000W yog haum. Lub vuam ceev yuav tsum phim lub zog. Piv txwv li, thaum lub zog yog 1800W, kev nrawm ntawm 5 - 7 hli / s yog qhov zoo tagnrho. Txoj hauj lwm tsom tseem cuam tshuam rau kev siv vuam. Lub ntsiab lus rau cov phaj nyias yog nyob rau saum npoo, thaum rau cov phiaj tuab, nws yuav tsum tau ntxaum sab hauv.

3. Tswj ntawm cov lus qhia tshav kub

Aluminium hlau muaj lub siab thermal conductivity thiab yog nquag ua kom sov sov, uas cuam tshuam rau Weld nkag thiab lub zog. Kev tswj hwm kev tswj hwm ntawm cov kev tawm suab sib kub. Piv txwv li, thaum ib tus aerospace kev lag luam welded aluminium qhov chaw, kev tswj hwm tsis zoo ntawm cov lus qhia tshav kub coj mus tsis tiav kev lom zem ntawm Weld. Qhov teeb meem tau daws teeb meem tom qab ua tau zoo txheej txheem.

4. Daim Ntawv Thov Kev Tiv Thaiv Cov Roj

Kev tiv thaiv cov kev tiv thaiv kom tsim nyog tuaj yeem tiv thaiv weld oxidation thiab porosity. Argon, Helium lossis lawv cov mixtures feem ntau siv, thiab cov kev taw qhia txaus thiab tshuab taw qhia yuav tsum tau hloov kho kom zoo. Kev tshawb fawb qhia tau hais tias ib tug nqi ntws ntawm 15 - 20 L / Min thiab kev coj ua kom tsim nyog tuaj yeem txo cov porosity.

Yav tom ntej, nws yog qhov xav tau tias lub zog siab dua thiab muaj tswv yim zoo ua kom zoo nkauj thiab cov cuab yeej siv hluav taws xob tawm tsam thiab cov khoom siv tshiab yuav tseem txhawb nqa cov ntawv thov dav. Hauv kev xaus, tsuas yog ua raws li cov kev ceevfaj no, tsim kev ua kom zoo thiab ua kom zoo dua cov txheej txheem tuaj yeem ua rau pab txhawb kev lag luam ntawm kev tsim khoom lag luam.

Lub Sijhawm Post: Jul-12-2024